PRODAN interior

“We could have been the cheapest or fastest furniture manufacturer. Instead of fighting for an imaginary and temporary leadership position ... We have worked hard and conscientiously to become a unique furniture manufacturer.”

— Daniel Hacaj (owner and CEO)

PRODAN Interier is one of the basic pillars of our company. The first and most important building block, PRODAN Interier is the element on which the brand was built with German precision and awareness of Slovak society. The department consists of a group of qualified and experienced project managers who are responsible for the complete design process and, in cooperation with the client, architect or developer, transform visions and ideas into reality.

The task of the PRODAN team is to transform dreams from paper into “reality” in a way that preserves the client’s values and requirements as much as possible. In addition to our great, technically skilled and experienced colleagues in design, many high-quality and experienced colleagues in production are urgently needed in order to turn the drawings into a quality piece of furniture. The production part of our interior department is composed of the best specialists in their crafts.

The professional skills of our production team reach a high level, because of which we are able to carry out the implementation of atypical production with any available materials while maintaining the most sophisticated and modern procedures. In our team, we emphasize the accuracy and precision of each process.

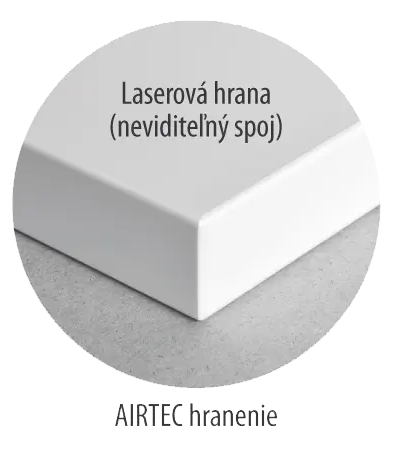

In order for the interior department to be able to take care of the client and provide them with above-standard service and one hundred percent product, our production and processes are constantly being improved and developed. Because of this, our production today has a sophisticated, fully automated cutting centre, a 5-axis CNC machining centre, our own paint shop and other technical facilities that enable us, for example, to finish sheet material with a “laser edge”.

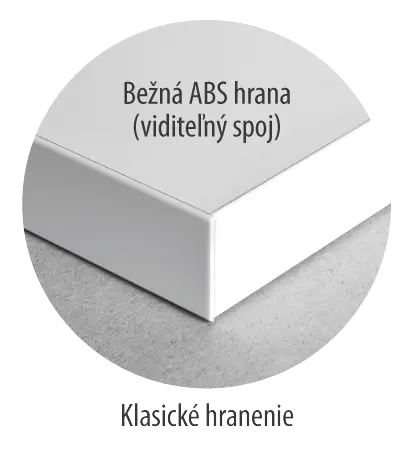

Our HOMAG professional edge bander has the function of gluing ABS edges using PUR technology with an adhesive or a function of seamless gluing with Laser Edges using HOMAG airTec technology.

Advantages of PUR adhesive over conventional EVA adhesive

- the joint has a very high strength

- high moisture resistance – suitable for bathroom furniture (PUR adhesive will not allow vapour to pass through the adhesive joint to the interior of the chipboard, thereby preventing damage from the inside to the chipboard, which is degraded moisture)

- high heat resistance of the adhesive – the edge withstands extreme temperatures from -30 °C to +150 °C

- high resistance of the adhesive joint to the action of chemicals – suitable for laboratory furniture

PUR ensures an extremely strong bond and because of the lower amount of applied glue, a minimal joint is created, which significantly increases both the visual and qualitative aspects of the banded furniture - the joint is far more resistant to wear and dirt

HOMAG airTec technology

Our company uses technology from the German company HOMAG, which is a pioneer in zero joint technology. HOMAG developed airTec technology, which has revolutionized the furniture industry. The innovative technology enables hot air to melt the functional polymer layer on the underside of the coextruded edge, thereby creating a solid bond between the edge and the plate. This technology completely eliminates the use of adhesive, creating a durable joint with a zero joint between plate and edge. It creates a high-quality look that feels like it’s a single piece.